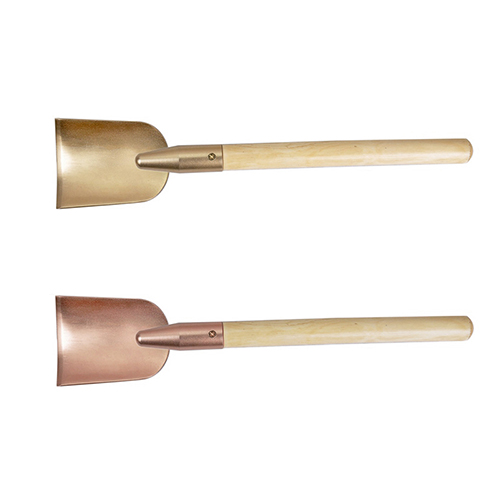

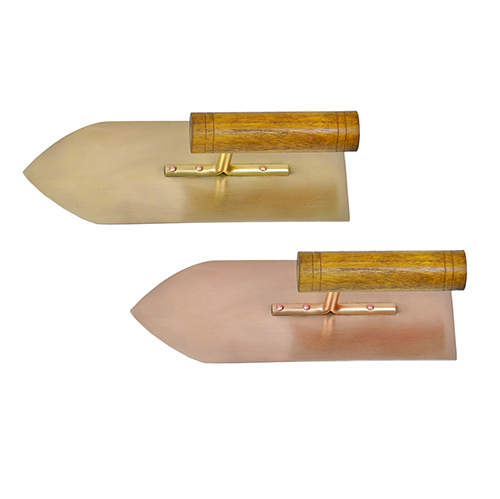

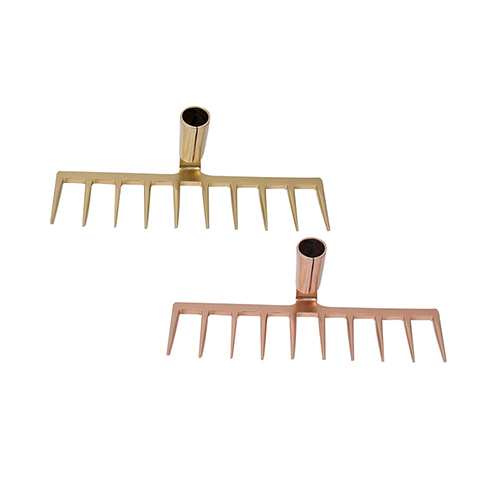

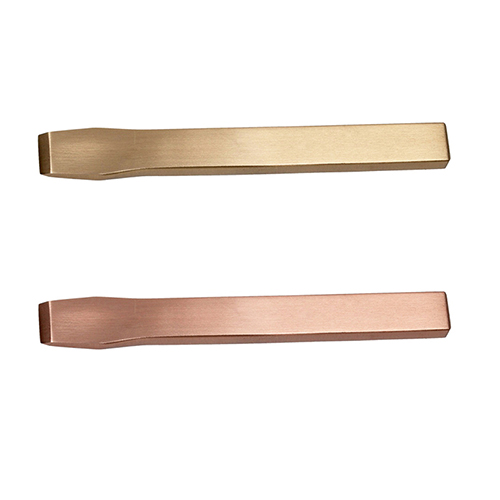

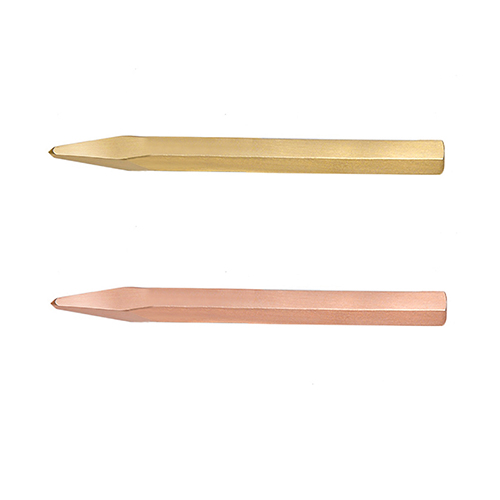

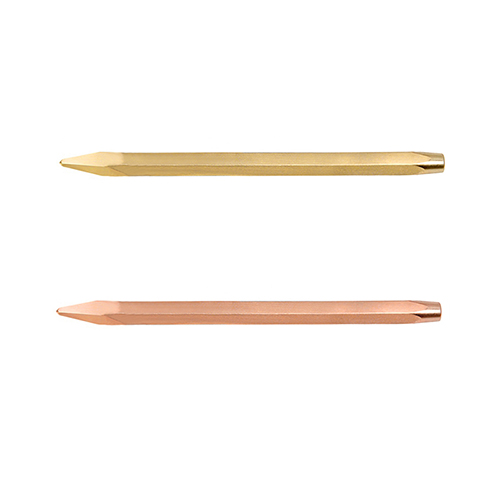

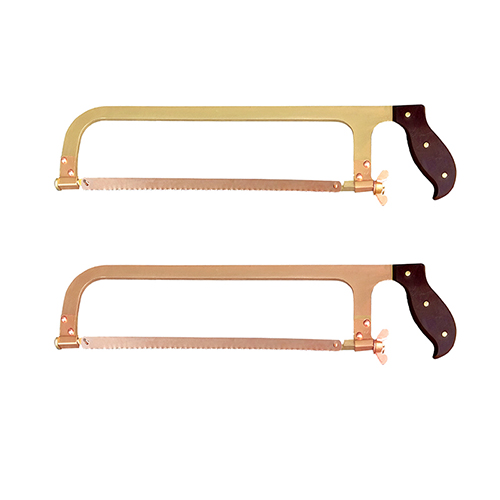

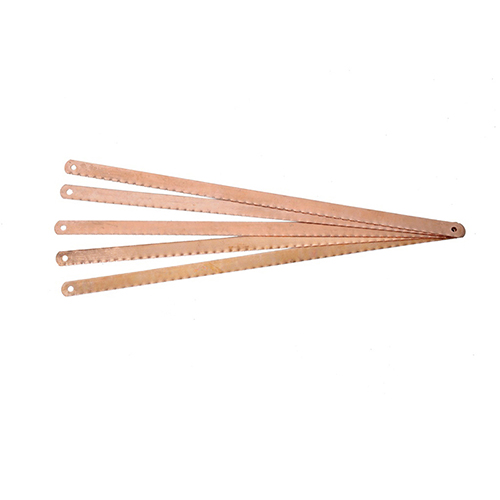

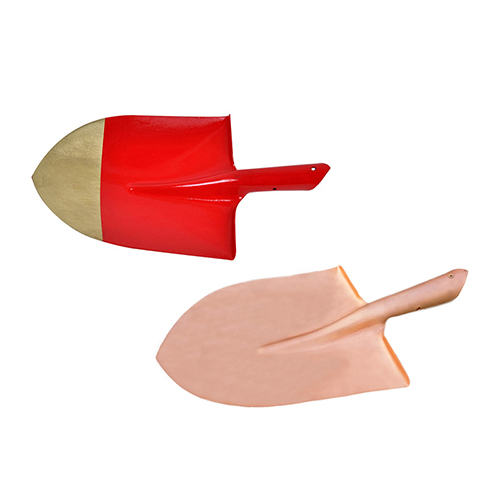

NON-SPARKING SAFETY TOOLS

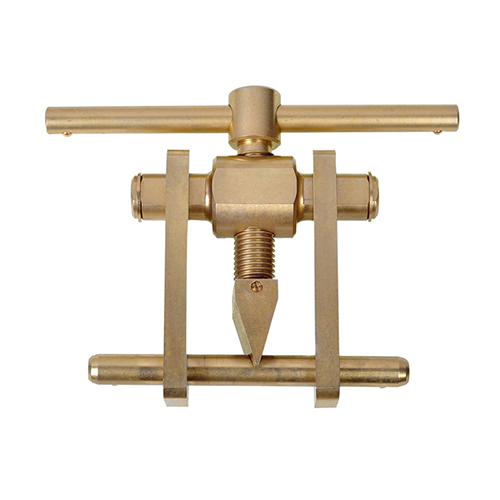

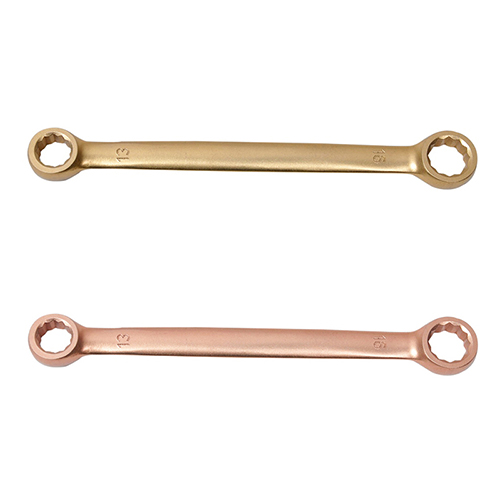

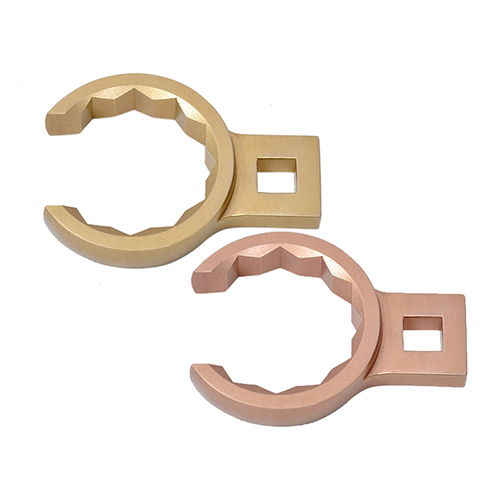

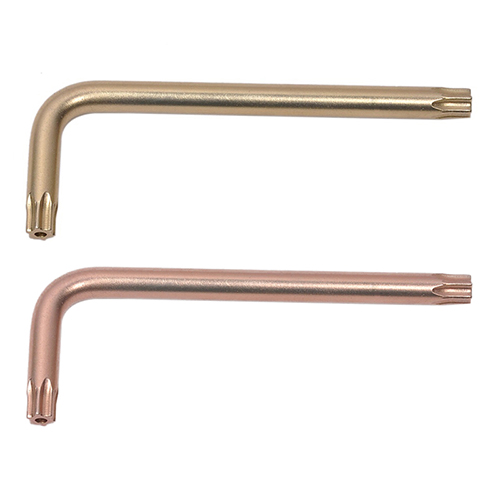

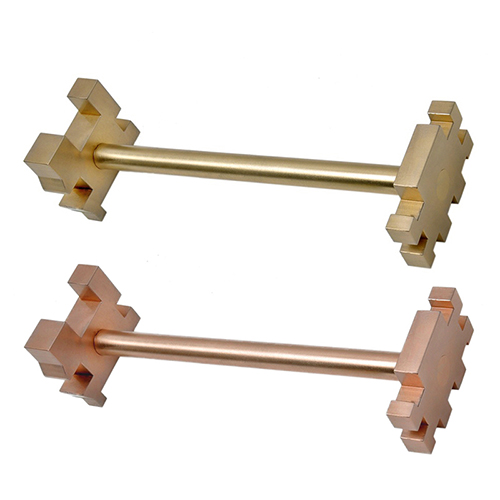

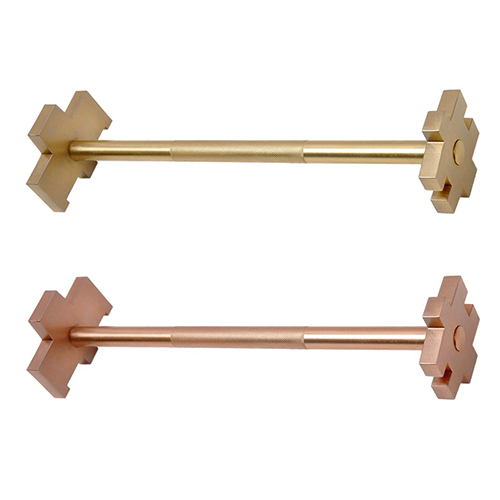

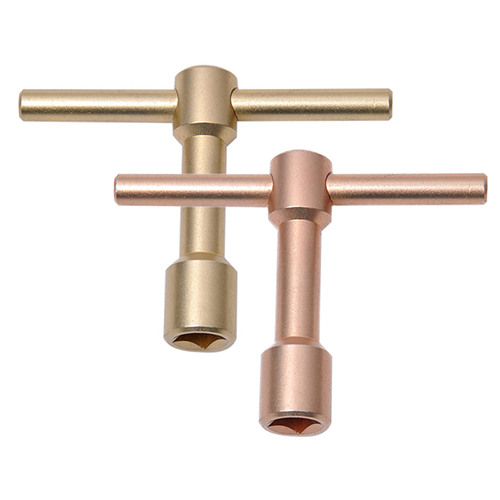

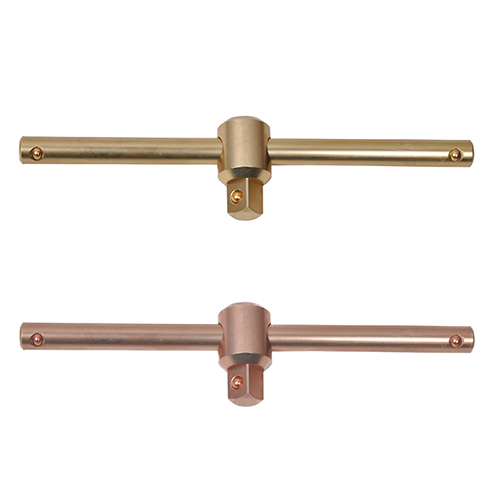

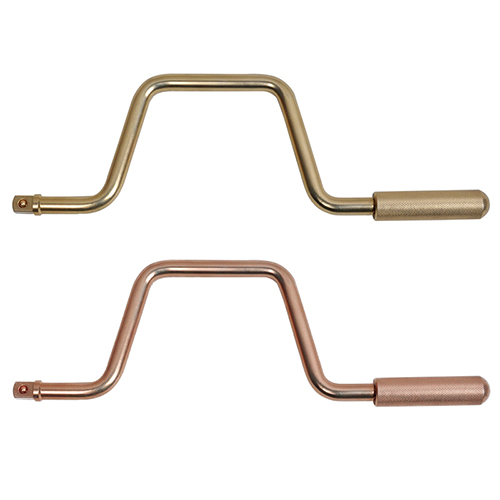

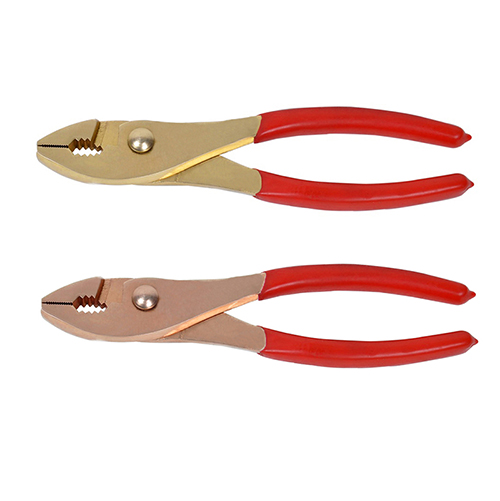

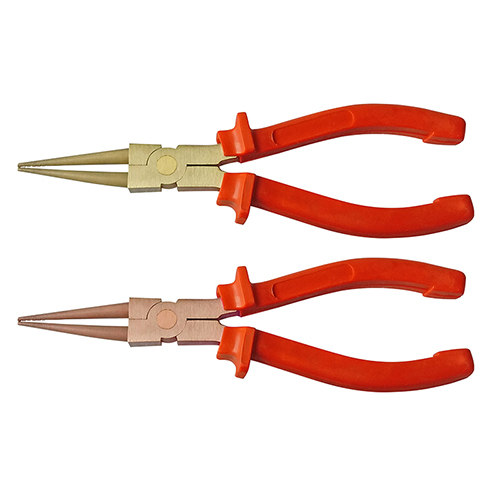

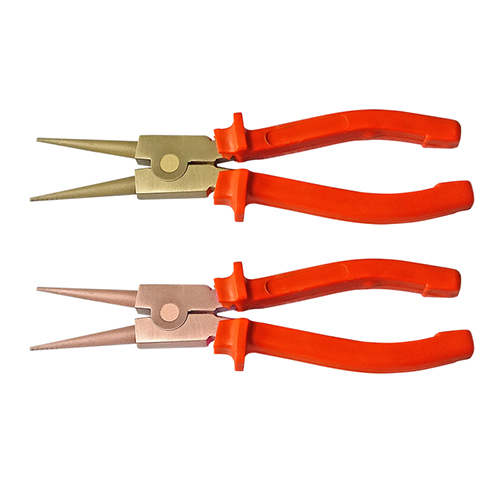

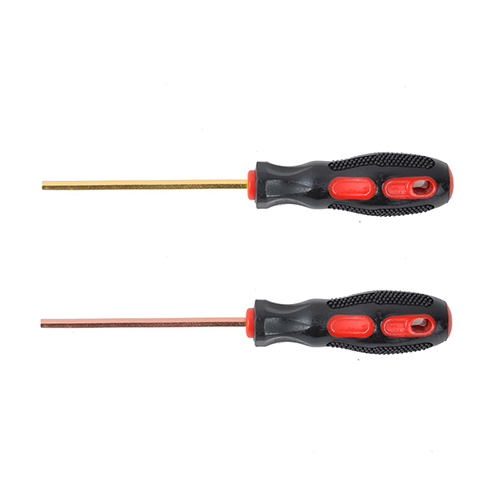

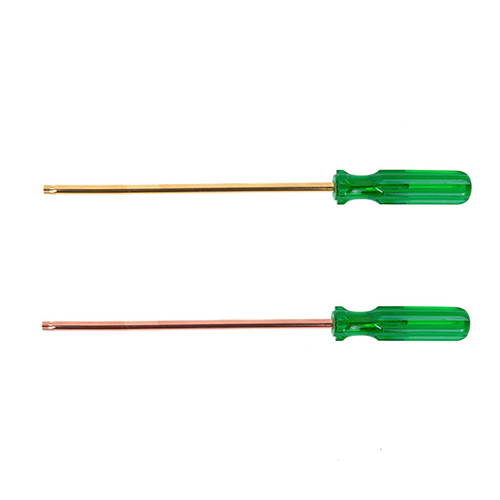

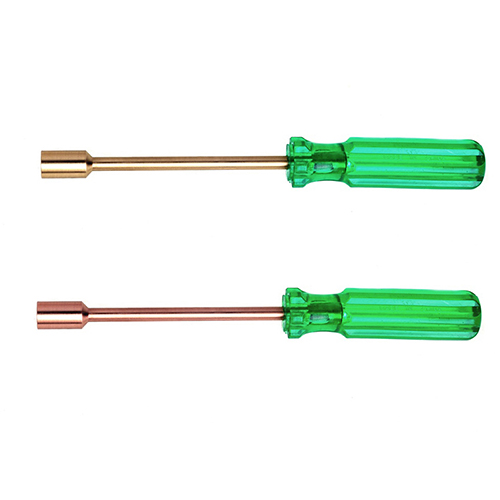

Our non-sparking safety tools are manufactured from aluminium-bronze (Al-Br.) and beryllium-copper (Be-Cu) alloy and are suitable to prevent friction between tools and work materials, as well as combustible explosions caused by collision, ensuring both personal and property safety.

Our non-sparking tools are used around the world in key industries such as:

- Oil, gas, petrochemical

- Pyrotechnics

- The manufacture of explosives, flammables

- Breweries, distilleries, food processing industries

- The manufacture of paints

- Demining, shipbuilding, aerospace

ALL our products are manufactured under ISO9001and UKAS.

How to choose the right material for your tools

- Aluminium Bronze

- ZoneFulfil ATEX Directive

- 94/9/EC for work i Zone

- 1, 2, 21, and 220

- Hardness27 HRC

- DurabilityNot as strong as BeCu

- MagneticLow magnetism due to low Non ferrous components.

- Composition:AL10% FE 4,5% Ni 4,5% Other 0,5%

- Balance CU

- Beryllium Copper

- Fullfill ATEX Directive

- 94/9 for work in zones

- 0,1,2,20,21

- Hardness 38 HRC

- Very strong due to good hardness and tensile strenght

- Non ferrus components for tools demanding non

- magnetic properties.

- Composition: Be 1,9% Co+Ni 0,4% Other 0,5%

- Balance Cu

Feel free to contact us and we will do our best to manufacture the tool for you.

Phone +45 50 41 66 89

About

Ti.Ha. Trading

CVR: 33688172

Address

Agervej 33

4200 Slagelse

Contact

Phone: +45 50 41 66 89

E-mail: hanstiha@gmail.com

Double-open-end-wrench锻.jpg)

Double-end-box-wrench-offset锻.jpg)

锻.jpg)

.jpg)

.jpg)

铍铜.jpg)

.jpg)

铍铜.jpg)

.jpg)

铍青铜.jpg)

.jpg)

铍铜.jpg)

Wrench-SwedishType-45.jpg)

Screwdriver-bits-slotted.jpg)

-Screwdriver-bits-Phillips.jpg)

Screwdriver-bits-Pozidriv.jpg)

Screwdriver-bits-hex.jpg)

-Screwdriver-bits-ballpoint-hex.jpg)

-Screwdriver-bits-torx.jpg)

Screwdriver-bits-hex-nut.jpg)

Shovel-square-with-D-handle.jpg)

Shovel-round-point-with-D-handle.jpg)

Shovel-scoop-with-D-handle.jpg)